Inductive Encoder Chips extend lifetime of 3D Printers

- sietsewouters

- Aug 3, 2022

- 1 min read

Updated: Aug 24, 2023

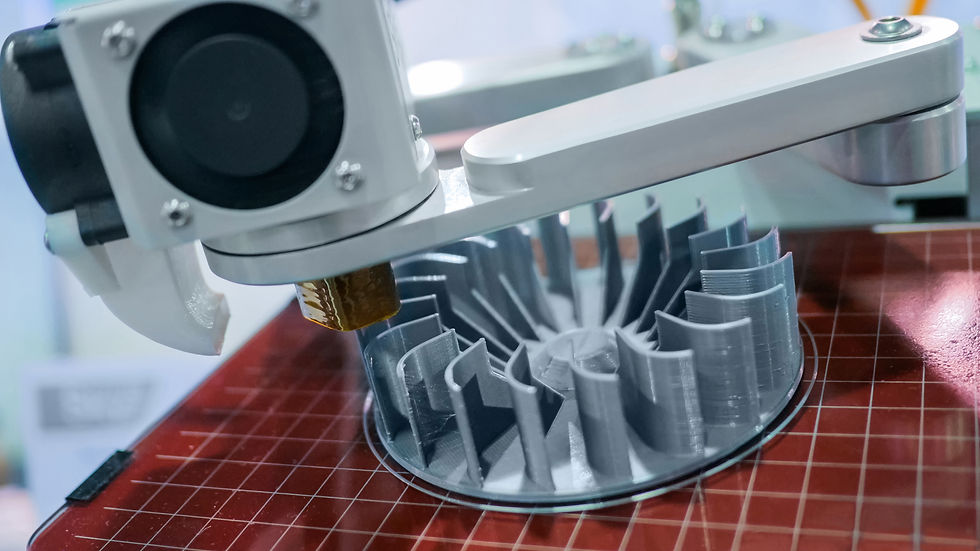

3D Printing typically requires high resolution and accuracy, so optical encoders are often used to control the rotary and linear movements of the printing head. During the 3D printing, the printing-material circulates in the printer and should only be deposited on the object that is created. However, a very thin layer is deposited over time on the inside of the 3D-printer, including on the optical encoder(s) and the optical scales and codewheels. Over time, this may affect the accuracy and the reliability of the encoder, ultimately leading to a malfunctioning or a non-functional encoder.

Inductive encoder chips are insensitive to any plastic, glass, ceramic or organic layer deposited on the encoder chip or on the scale or disc. Even a thin metallic layer up to a few micrometer would not impact the functionality, thus extending the operational lifetime of 3D printers.

Furthermore, POSICoder's encoder chips have small dimensions and a very low mass, which makes them really suitable for integration in 3D-printers.

What is the best way to get started with POSICoder's encoder chips?

We recommend to order an Evaluation Kit, which contains encoder-configuration software, an interface board, 2 cabled encoders, 5 encoder chips, 4 scales and 4 discs.

Comments